whats the ac fan

Introduction

So what is the AC fan? It is a device that cools using alternating current (AC). AC fans are important. They assist in maintaining the comfortably cool living and working areas. Furthermore, AC fans are commonly used in the industrial sector and the telecommunications industry for cooling and heat transfer applications. We will look into the workings of AC fans in this guide. It will cover their kinds, uses, power consumption, and how to select the proper AC fan for you. Prepare for a trip that you will be proud of, as you will be able to see these masterpieces of engineering. They are the reason we can stay at a pleasant temperature while consuming less energy.

What is AC Fan?

An AC fan is an electrical device that works on alternating circuits to create airflow. It is commonly used in numerous cooling systems to discharge heat from components and equipment, thus, keeping them at the right temperature. AC fans are widely used across all major sectors, from computers and electronics to industrial machinery and automobiles, making them an essential component of AC outlets.

The manufacturing of an AC fan is simple, consisting of components like a motor, blades, and housing, and hence manufacturing of these components is a cost-effective process. Even though they are not the most complex devices, AC fans can still do a great job of providing the necessary airflow and operate at low noise levels. This is a plus that makes them appropriate for places where there is a need for ventilation or air conditioning, for instance, factories, warehouses, retail stores, offices, and residential spaces.

How Do AC Fans Work?

AC fan mode is based on the construction of an induction motor and its working principle. It is made up of a stator that is stationary and a rotor that rotates. The stator being connected to an alternating current source results in the windings within the stator generating a rotating magnetic field, which in turn makes the rotor spin. This rotational motion is then transmitted through the blades attached to the rotor shaft.

The blades rotate at a high velocity, and, in the process, they give the air molecules a lot of kinetic energy and create a continuous flow of cool air. The profile and the airfoil design of the blades determine the direction, speed, and pressure of the airflow generated. The manufacturers of the best AC fans achieve this by designing the blades and the housings in such a way that they not only provide maximum airflow but also ensure that the air flow is optimized to the cooling needs of the different applications.

It is worth mentioning that alternating currents can generate electromagnetic interference (EMI) which probably may affect nearby electrical devices. Therefore, the AC fans are developed in such a way that they avoid such interference and are compatible with other electrical equipment present in the vicinity. AC fans are also equipped with many fan settings, which allow users to control the airflow speed based on their personal needs.

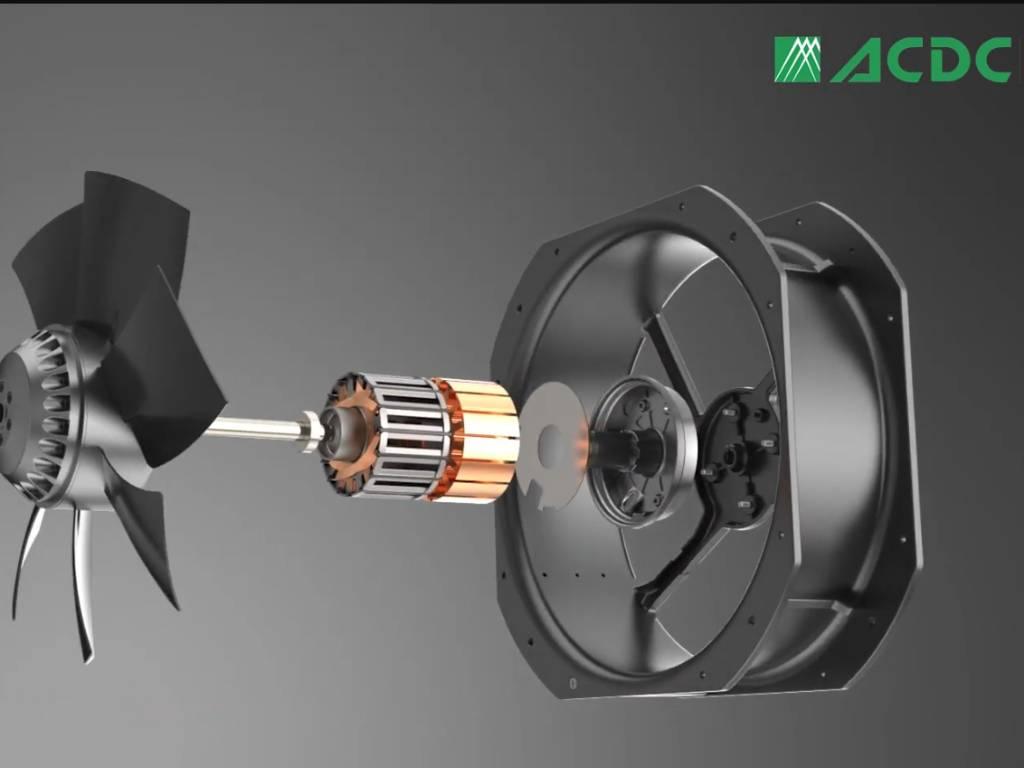

Key Components of AC Fans

The AC fan designs could be different and may have some modifications. However, most share a few key parts:

-

Stator: This is the section that does not move. It is a coil of electromagnets. These coils provide rotating magnetic fields.

-

Rotor: The rotor is usually a permanent magnet or an electromagnet. It interacts with the magnet fields of the stator. This makes the rotor rotate.

-

Blades: The blades are attached to the rotor. They spin and produce the required air movement.

-

Motor: The motor has two main parts, the stator and the rotor, which are located in the motor. It transforms electrical energy into mechanical motion.

The process works like this:It is the responsibility of all stakeholders to recognize the importance of this issue and actively contribute to finding viable solutions. It is the alternating current that passes through the stator coils. This results in a permanently changing magnetic field. Next, it is the turn of this field to interact with the magnetic field of the rotor. Because of that, the rotor starts to spin. In this way, the spinning rotor causes the rotating blades. This rotation generates airflow.

The blower fan is the one that pushes the cold air through the whole system. Furthermore, most AC fans can be set to different fan speeds. This grants users the ability to modify airflow speed according to their current requirements.

Components of AC fans

Types of AC Fans

Axial Fans

Axis fans are one of the most common types of AC fans. The blades are placed along the axis. The airflow moves in parallel with the shaft axis. The fans are capable of delivering high airflow rates. They are also quiet and very efficient. On the other hand, they have lower static pressure.

In a wide range of applications, axial AC fans are a common choice. These include cooling electronic devices, HVAC systems, and industrial ventilation systems. They are excellent in places where high cooling function and air quality are the key factors. They are able to effectively distribute cool air all over the system. In addition, they reduce the level of noise pollution.

Centrifugal Fans

Meanwhile, centrifugal fans have different fan settings. Its blades are arranged in a circular fashion, like a propeller. The fans of this type have airflow that moves outward at a right angle to the shaft axis. The centrifugal fans can develop high static pressure. They also have high airflow rates. Nonetheless, they are noisier. It is also worth mentioning that their peak efficiency level is lower relatively.

However, these trade-offs notwithstanding, centrifugal AC fans are still very popular. They are designed for applications that require high-pressure air flow. Such systems include boiler air supply systems, industrial dust collection, and mine ventilation. Their robust performance allows them to work well in places where the humidity and air quality are strictly regulated.

Cross-Flow Fans

Cross-flow fans possess a hybrid design. They consist of a combination of an axial fan and a centrifugal fan. The blades are placed in spiral form. This kind of flow permits air movement in both directions—axially and radially.

This exclusive arrangement gives cross-flow fans have certain advantages. First, they can produce a high airflow rate. The next thing is that they produce medium level static pressures. Additionally, their noise intensity is also moderate. Additionally, they have high efficiency.

Cross-flow fans are one of the most versatile AC fans. They are the most popular products in numerous industries. Likewise, they are used for tunnel ventilation, ventilation in metal factories, and power plant ventilation. This balanced performance offers an opportunity to satisfy different cooling and airflow requirements. On the other hand, they lead to energy savings (less power) and noise reduction.

Quite a few utility companies and industrial facilities choose cross-flow fans. The reason is its cool mode and high efficiency overall. They are a perfect fit for companies and facilities such as these.

| Type of AC Fan | Features and Specifications |

| Axial Fan | – Suitable for cooling applications – Moves large volumes of air at low pressure |

| Centrifugal Fan | – Delivers high airflow – Enhances air quality and controls indoor humidity |

| Cross-Flow Fan | – Provides excellent cooling performance – Operates quietly |

The Importance of AC Fans in Cooling Systems

We have looked at the various types of AC fans. Now, we will discuss the function of the radiators in the cooling systems. We will understand why they are an integral part of contemporary climate control tools.

Compact Cooling Fans

Enhancing Air Circulation and Ventilation

One of the main functions of air conditioning is air circulation and ventilation. These fans are designed for the purpose of conveying air through a space or system. They help regulate temperatures. They remove stale air. In addition, they contribute to the inflow of fresh, cooler air from the outside.

Air circulation has to be proper. It provides a suitable indoor atmosphere. It also avoids the formation of dust, moisture, and odor. In industrial environments, good ventilation is often a must for safety reasons. It serves to remove dangerous gasses, dust, and other pollutants from the air.

Enhanced Heat Transfer Efficiency

AC fans are one of the most important elements that increase the efficiency of heat transfer in cooling systems. They improve airflow over heat-generating parts or heat exchanger surfaces. This is a mechanism that enhances the heat dissipation process.

As in air conditioning systems, AC fans work in tandem with compressors, condensers, and evaporators. They circulate the cool air all around the designated area. Likewise, the AC fans in computers and servers evacuate the hot air from the components. It prevents overheating and thus ensures the best performance.

Reduced System Temperatures

AC fans in cooling systems are mainly used to bring down the overall temperature of the system. They provide for effective heat transfer and air movement. This is meant to ensure that the various parts and systems in the engine work at the best temperature.

Lower temperatures contribute to more comfortable conditions. Besides, they extend equipment’s life and guarantee their high quality. Overheating may result in component breakdowns, reduced efficiency, and higher energy consumption. AC fans can be used in cooling systems to engineer compact, efficient, and long-term solutions.

AC Fan Applications

AC fans have many uses in different sectors and industries. These are because of their versatility and the fact that they cool faster.

Electronics Cooling: In many electronic devices, AC fans are widely used to get rid of heat. They help electronic components to avoid overheating. Overheating can lead to performance problems or damage. AC fans are located in computers, servers, and communication equipment. They are the ones that dissipate heat from CPUs, hard drives, memory modules, power supplies, transformers, and amplifiers. This ensures reliable operation.

Industrial Ventilation: AC fans are versatile in industrial applications. These include ventilation, dust collection, process cooling, and material handling. They help in removing hazardous substances like dust and fumes. It does not only purify the air in workshops but also. Moreover, fans also help in the transfer of heat. They provide the necessary oxygen for the combustion chambers. This is an improvement in the heating efficiency of related processes.

Industrial Ventilation

Agricultural Applications: Crop drying, cooling, and ventilation are carried out with agricultural fans. They raise crop quality and quantity by sending fresh air.

Medical Ventilation: In medical facilities like operating rooms and laboratories, AC fans are employed for ventilation and air purification purposes. They are responsible for the regulation of bacteria, viruses, and other pathogens in the air.

AC fans provide a great way to ensure the right working conditions throughout the whole range of these applications. They offer efficient air circulation, heat mode, and temperature regulation. This in turn leads to higher productivity, better quality, and performance. Routine AC service and selecting the right fan speed are a must. This is based on the amount of moisture and temperature set in the unit. It is an optimal use of these cooling solutions, which are multi-functional.

Selecting the Right AC Fan for Your Needs

Criteria for selecting the proper AC fan cover a wide range of considerations, including airflow requirements, static pressure, noise levels, and energy efficiency. These factors can make a huge difference in power usage and cooling efficiency.

It is very important to identify your specific needs realistically. It encompasses the selection of the size of space/system to be cooled, the heat load generated by the components, and the desired temperature range.

You can get help from the experts or from the well-known manufacturers to be your guide. ACDCFAN produces and manufactures small cooling fans that are used in a variety of industries, ranging from industrial machinery to electric power, photovoltaics, energy storage, and telecommunications. The fans they produce include AC axial fans, AC centrifugal fans, DC axial fans, DC blowers, and EC axial fans. These are distributed to customers worldwide.

ACDCFAN has been leading the industry, consistently delivering high-end products to cater to the various demands of customers in minimal expense. Their cooling fans are certified to ISO 9001 and ISO 14001, and they meet the regulations of UL, CE, and TUV, which are the highest standards. They are RoHS compliant as well.

Conclusion

Knowing the role of AC fans in cooling systems is a critical factor in achieving the best results. Thanks to their air circulation, ventilation, and heat transfer efficiency, AC fans are very significant for the reduction of the system temperatures. Whether you are looking for an axial, centrifugal, or cross-flow fan, choosing the right type is vital to meet your particular needs. In case you need expert advice on the selection of the right AC fan for your purpose, just make a free appointment with us right now.